SLIC™ Friction Reduction Coating

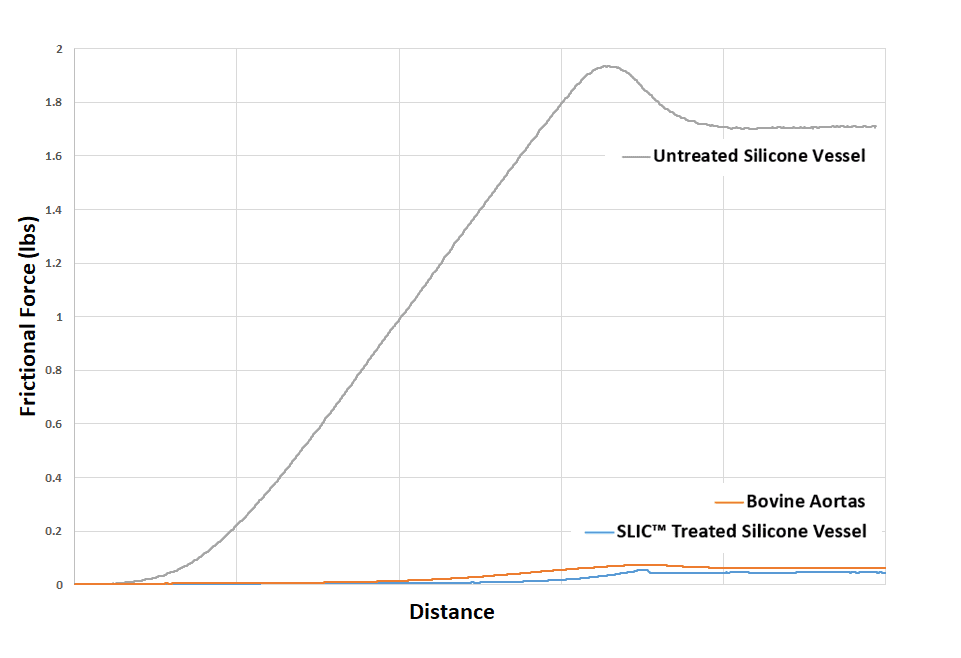

The use of silicone for manufacturing complex vascular models and simple arterial or venous vessels is common and advantageous for its transparency, stability and durability. However, the inherent tackiness of the final product causes challenges in the model’s use when tracking guidewires, catheters, delivery systems and similar technologies due to the ‘stick-slip-stick’ response.

BDC Laboratories SLICTM lubricious coating is a proprietary surface treatment that serves to achieve a clinically relevant surface friction, specifically on silicone anatomical models. The SLIC coating offers a unique combination of friction reduction coupled with excellent bonding to native silicone vasculature and superior resistance to abrasion and erosion. BDC’s proprietary process for applying the SLIC coating produces an ultra-thin, gap-free, conformal coating of all exposed luminal silicone surfaces, providing a uniform, ultra-low-friction surface. The process also ensures that the compliance of mock silicone vessels is unaffected.

Advantages of Coating Silicone Vasculature with BDC’s SLIC™

- Produces a clinically relevant environment for tracking transcatheter devices, catheters, guidewires and delivery systems

- Creates a realistic experience for physician training of heart valve prostheses, stent and stent graft systems and other endovascular devices within silicone vasculature

- Reduces forces on delivery systems during advancement, deployment and retraction, preventing potential damage

- Eliminates ‘stick-slip-stick’ effect between silicone anatomical model and the delivery system to promote a higher level of deployment accuracy

To learn more about the benefits of SLIC™ coating and how it can make tracking and deploying easier and more clinically relevant, download our brochure. Better still, ask us for a free SLIC coated sample!