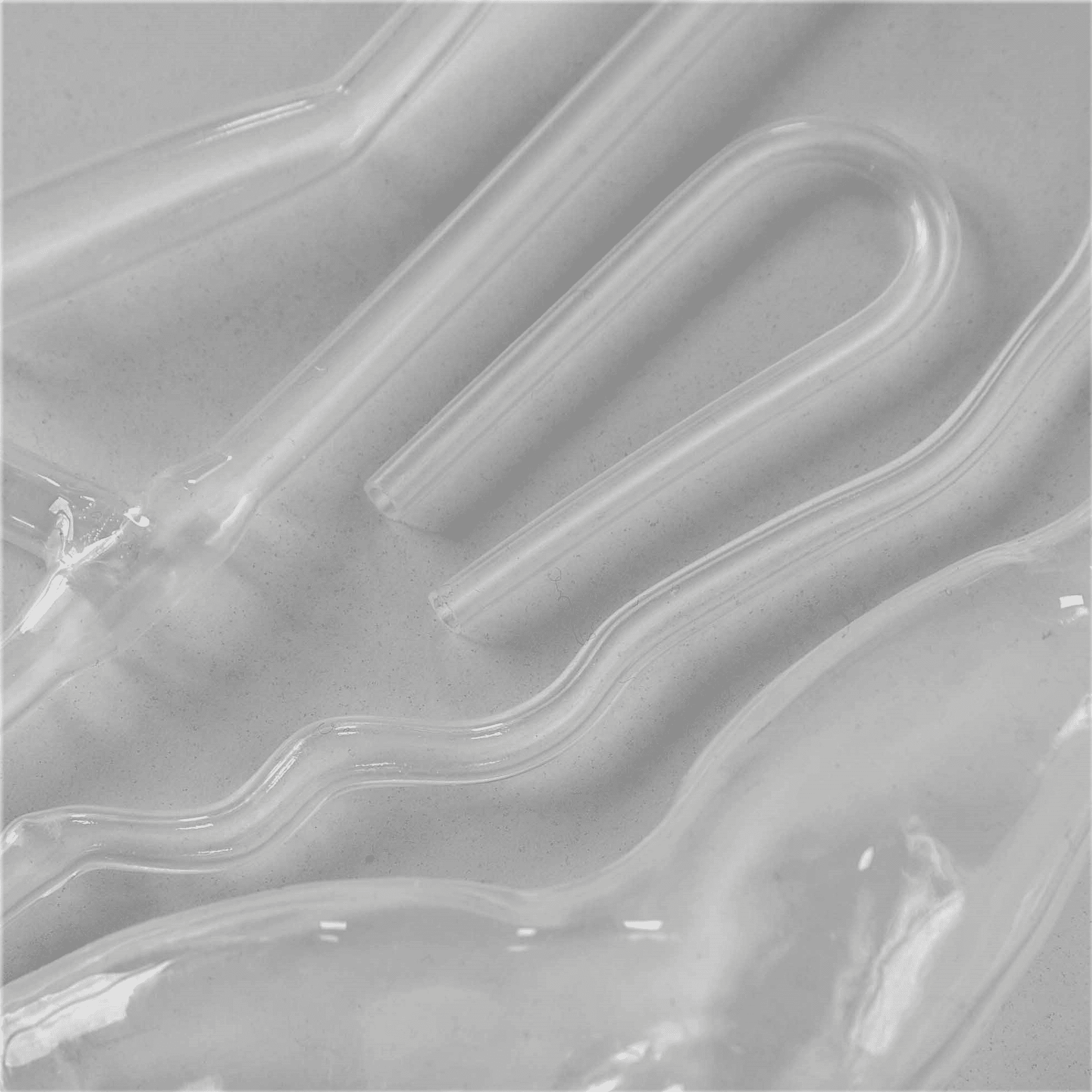

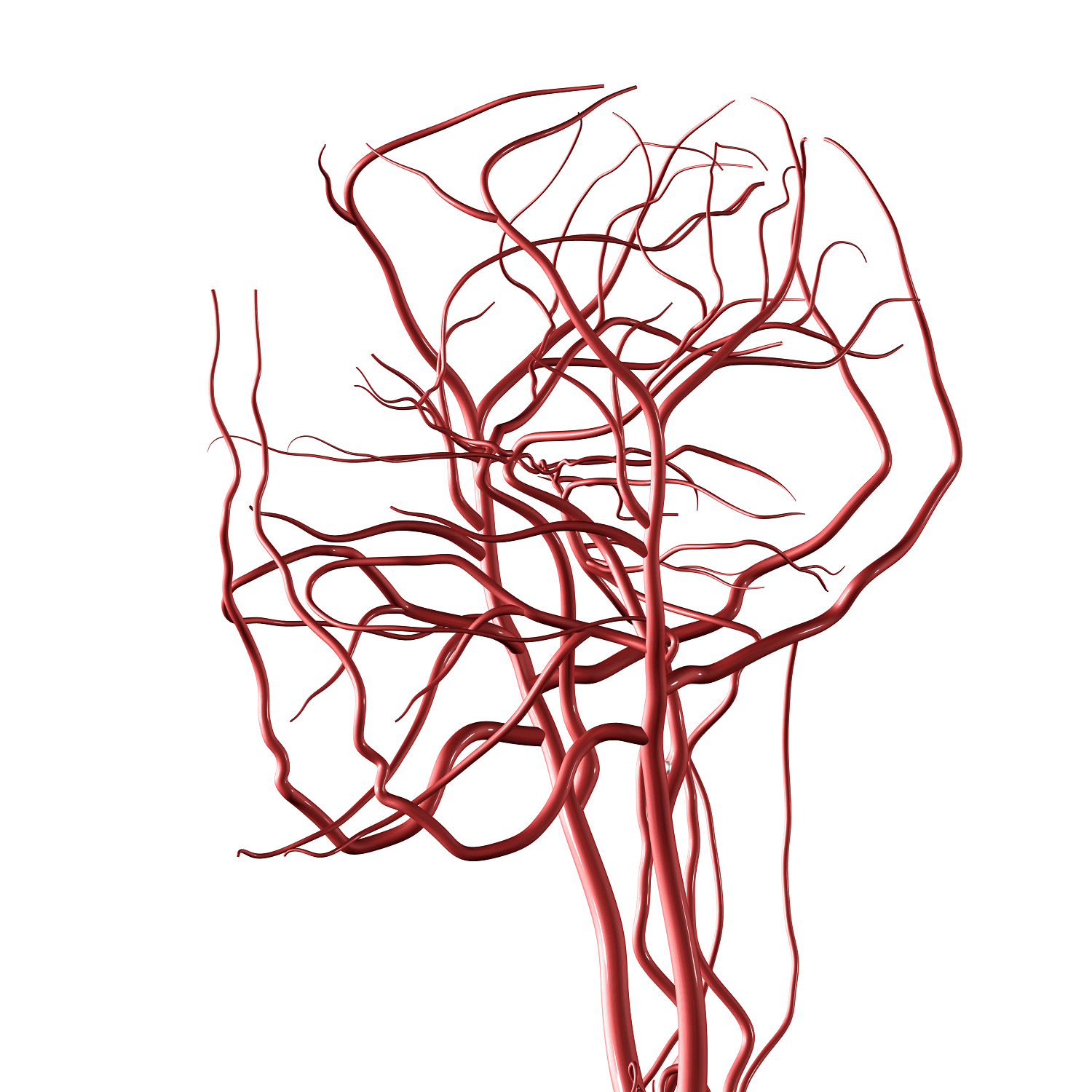

With over 15 years of experience in fabricating compliant silicone mock vessels and clinically accurate anatomical models of human and animal vasculature, BDC Laboratories leads the world in engineered silicone vasculature. BDC uses several proprietary methods to fabricate our silicone models for nearly all the world’s leading cardiovascular device companies.

Our silicone vasculature and mock vessels are commonly utilized for:

- Device development, testing and evaluation: The development process for transcatheter structural heart and endovascular devices, as well as catheter based therapies, greatly benefits from test platforms that accurately represent the clinical environment. With over 40 years of direct experience in the development and evaluation of these technologies, BDC is in the highly unique position of being able to apply this extensive experience to all our silicone vascular models, yielding superior platforms for device evaluation. Moreover, with internal capabilities to certify the dynamic radial compliance of our mock vessels to ISO 7198 & ASTM F2477, BDC can provide certified silicone vessels for durability studies, or other applications that require a specific dynamic radial compliance.

- Physician training and education: BDC specializes in engineered solutions to each of our client’s needs, which becomes indispensable when procuring silicone vasculature-based simulation solutions for physician training. Beyond the ability to design and manufacture the silicone vasculature for your training needs, BDC has an entire team focused on both standard and custom simulated use solutions for the training and education of transcatheter structural heart and endovascular technologies. Furthermore, with our proprietary SLICTM friction reduction coating, BDC’s models do not require the use of surfactants or lubricants to create a clinical experience in either a wet or dry model, providing physicians with the most realistic experience available.

- Marketing and sales demonstrations: Differentiating and showcasing your technology is key to expanding market presence and sales volume. BDC partners with each of our client’s to fully appreciate the strengths of their technology and what differentiates it within the marketplace. With this distinctive approach to our silicone anatomical model solutions, BDC is able to provide the ultimate platform to highlight your device and demonstrate its benefits and key attributes. With our proprietary SLICTM friction reduction coating, BDC’s models do not require the use of surfactants or lubrication in either a wet or dry models, providing a superior ease-of-use and demonstration experience.

Move Forward with BDC

Biomedical Device and Consultants & Laboratories will spend extra time to get you exactly what you need, at the best price. Questions that other companies will not be able to answer will be answered by Biomedical Device Consultants & Laboratories. From our experience, don’t spend extra time getting quotes from other companies, trying to find the best specs and material properties. Biomedical Device Consultants & Laboratories is the best place to meet your timelines.

Medtronic (Endovascular Division), Inc.

Read More