Cardiovascular Simulated Use Models

Showcase your products live with models

designed for display, training or both.

Demonstrate Your Value

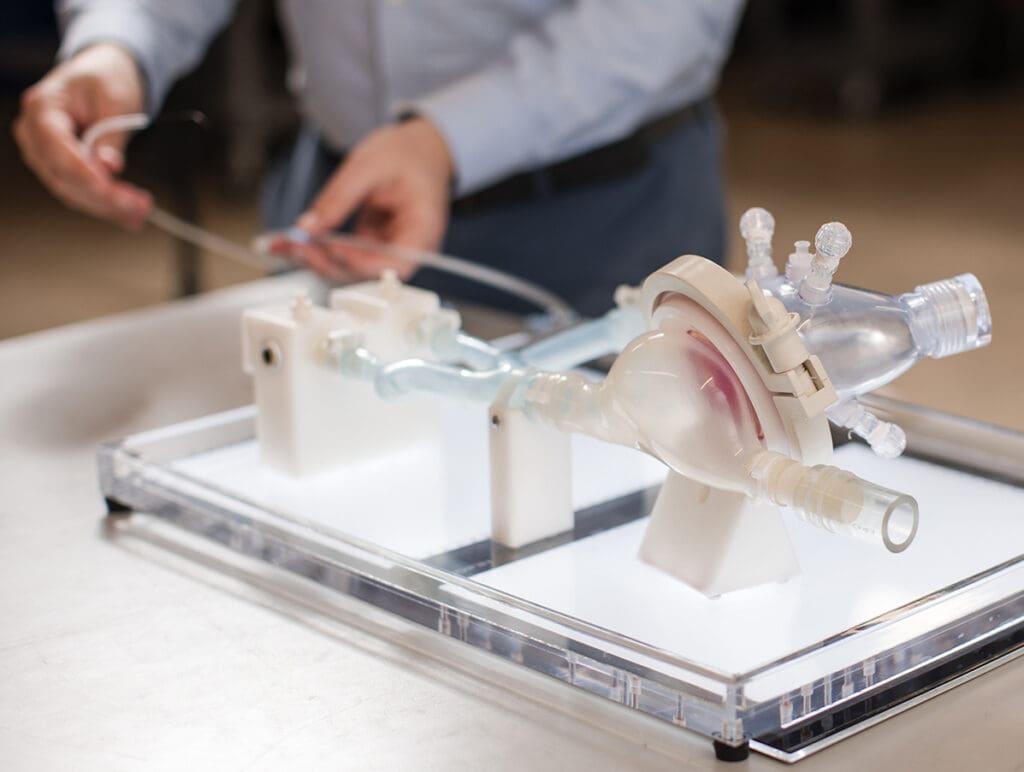

With stringent regulatory requirements, extensive testing, and high development costs, bringing new medical devices to market is a huge effort. Encouraging the adoption of your new or improved device starts with compelling, accurate models that demonstrate value. To best serve training and sales staff, models must be easy to transport, reliable, and evocative of scenarios in real care settings.

Simulation Models

BDC Laboratories develops customized, clinically relevant simulation models to represent patient anatomy and accurately show your device in real-world patient care scenarios. Moreover, we work with training departments to optimize setup, breakdown, and transport, while selecting materials best suited for your healthcare application.

Simulated Use Systems

SLIC™ Friction Reduction Coating

Silicone Vasculature Catalog

Medical Training Models

BDC Laboratories provides a quick, effective way to help healthcare professionals understand how to use your cardiac, endovascular, and vascular medical devices with custom anatomical models that are clinically relevant, portable, and include the anatomy you need and nothing else.

Customization

Starting with your patient scans or our optimized catalog of anatomies, BDC Laboratories consults with your team to create a simulation that best demonstrates your device’s utility. BDC Laboratories can customize attributes, including:

- Size and inner diameter (e.g. great vessels down to 2mm ID peripheral vessels)

- Tortuosity

- Flow capabilities (e.g. dry/open ended, fluid-filled or full pulsatile flow)

- Form factor (vessels alone to mounted on a tray for tabletop use)

- Relevant disease states or procedures (valve [TAVI, TAVR], stent placement, calcified vessels, etc.)

Combining creativity and engineering excellence

We are capable of much more than simple vessels and anatomies. Customers come to us with all sorts of devices that would benefit from custom cardiovascular and endovascular solutions, and we’re committed to creating simulations that highlight their products and capabilities.

Nick Flannery, Silicone Engineering Manager, BDC Laboratories

Resources

From Concept to Surgical Suite

See how we partnered with one American

medical technology company to create custom

simulations for complex cardiovascular

procedures.

Clinically Relevant Surface Lubricity

BDC’s SLIC coating treatment produces a uniform,

ultra-thin, gap-free, conformal and compliant

coated luminal surface that performs in a similar

manner when dry or wet.